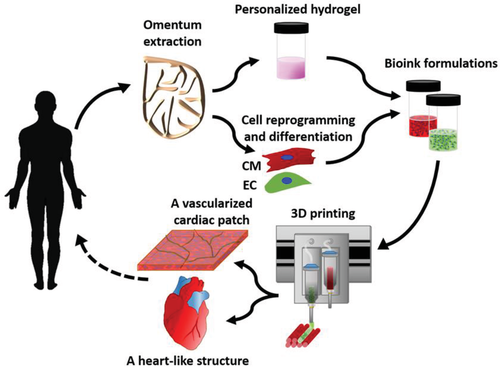

Researchers at Tel Aviv University managed to successfully created the world’s first 3D-printed heart that uses cells and biological materials from a patient.

The successful printed entire heart, completing with cells, blood vessels, ventricles and chambers, is a marked improvement over previous attempts that only printed simple tissues without vessels.

Fig Concept schematic of 3D printing Hearts

Source: 3D Printing of Personalized Thick and Perfusable Cardiac Patches and Hearts, advanced science, 2019

The heart isn’t very big — it’s only about the size of a rabbit’s heart. Currently, the hearts can only contract, which can’t be connected to vessels to be functioning. The technology just made it possible to have a human-sized organ. This 3D printed heart made from human cells advance possibilities for human transplants by preventing the possibility of rejection.

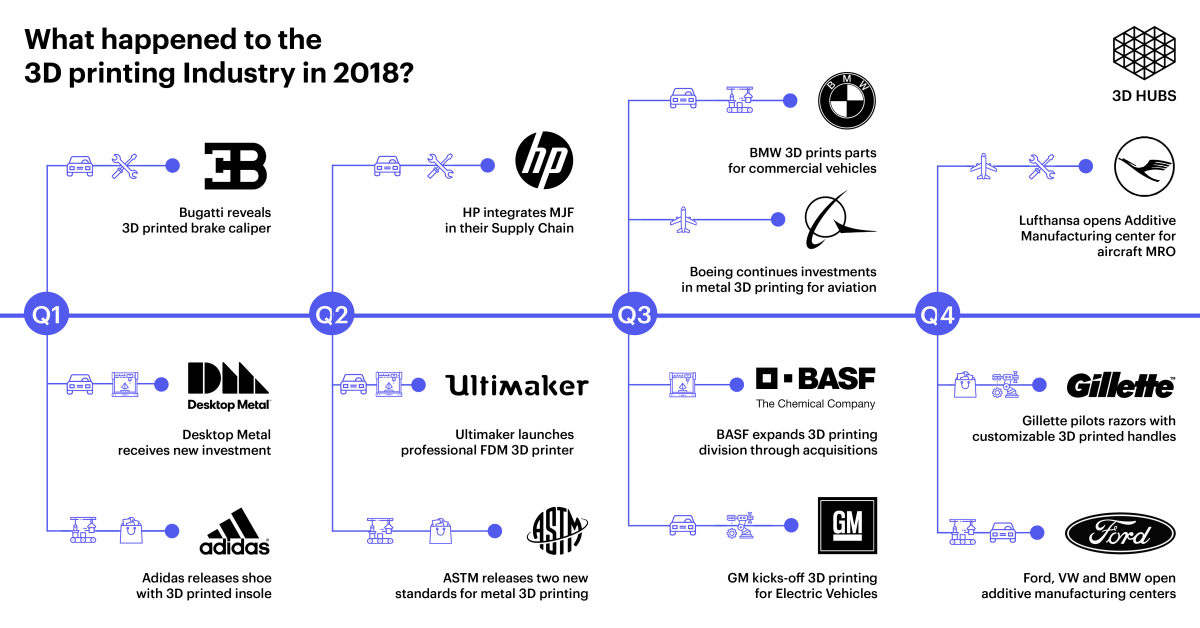

2018 saw a great deal of attention and excitement around metal 3D printing. A number of chemical companies including the likes of DSM, SABIC, BASF, Solvay, Mitsubishi Chemical, Arkema and Lehvoss, have demonstrated a growing interest in 3D printing as an industrial solution.

Companies such as GE, Airbus, and Royal Dutch Shell serve as early adopters, end-users, and investors in 3D printing technology.

Source:3D Hubs,IKMResearch,2018

GE, for example, is currently printing a jet-engine fuel nozzle for the CFM LEAP jet engine. The company also employs 1,000 material scientists in its GE Additive division. In 2016, it created a subsidiary, GE Additive, dedicated to the industry, and is reportedly building the world’s largest additive machine for 3D printing metal. GE has continued to hedge its bet on 3D printing by directly backing Carbon and Desktop Metal, participating in two rounds for each startup.

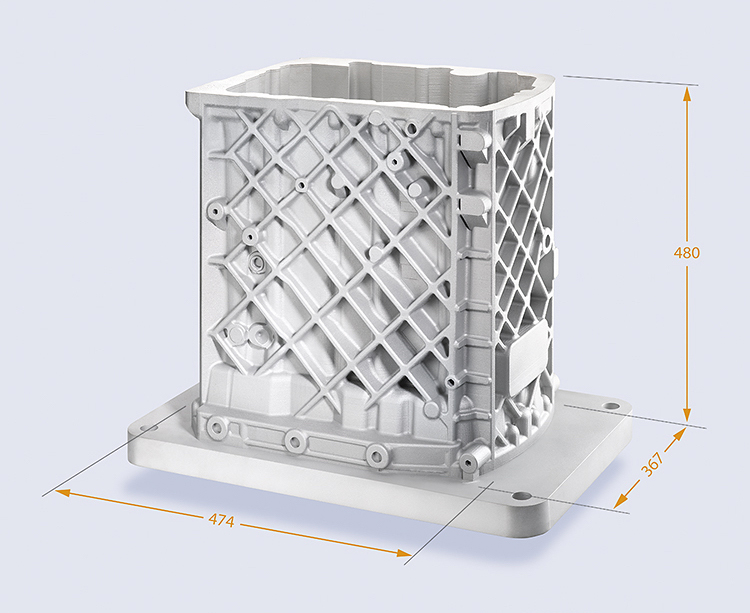

Fig. An engine block printed on a Concept Laser machine.

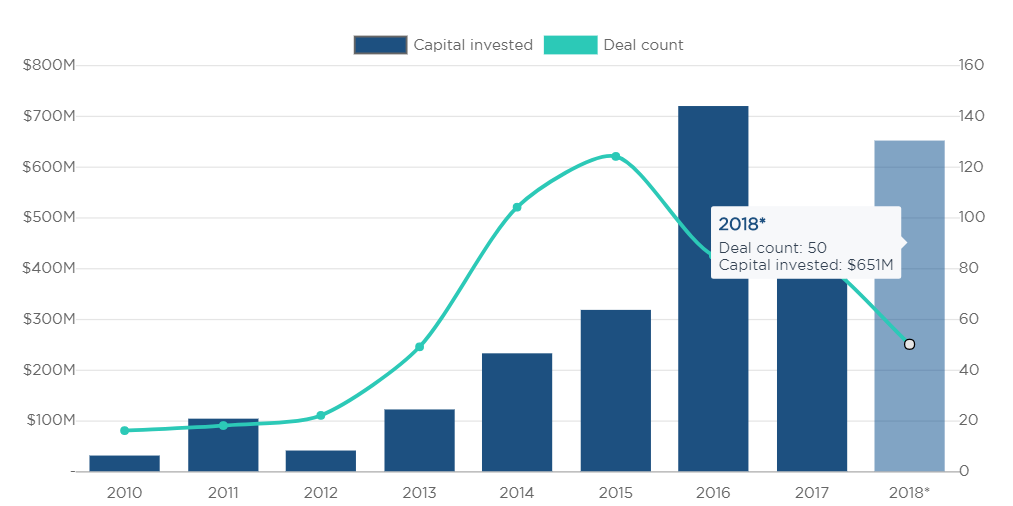

The 3D printing space has seen significant fundraising growth since 2013, with big manufacturing corporates like GE and Siemens investing heavily. Global spending on 3D printing will reach nearly $12B in 2018, according to IDC forecasts.

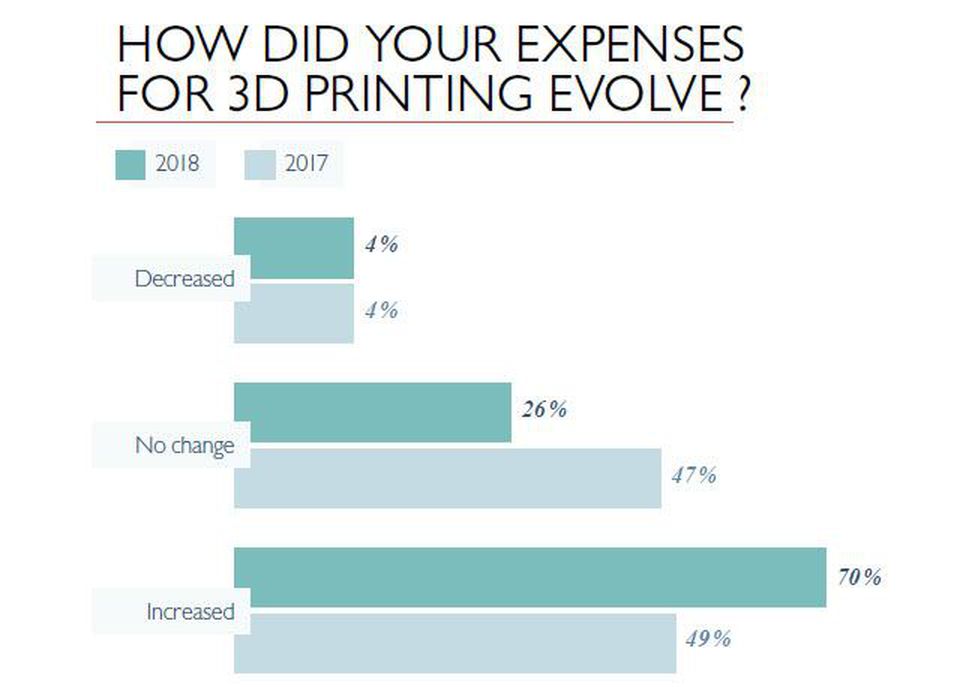

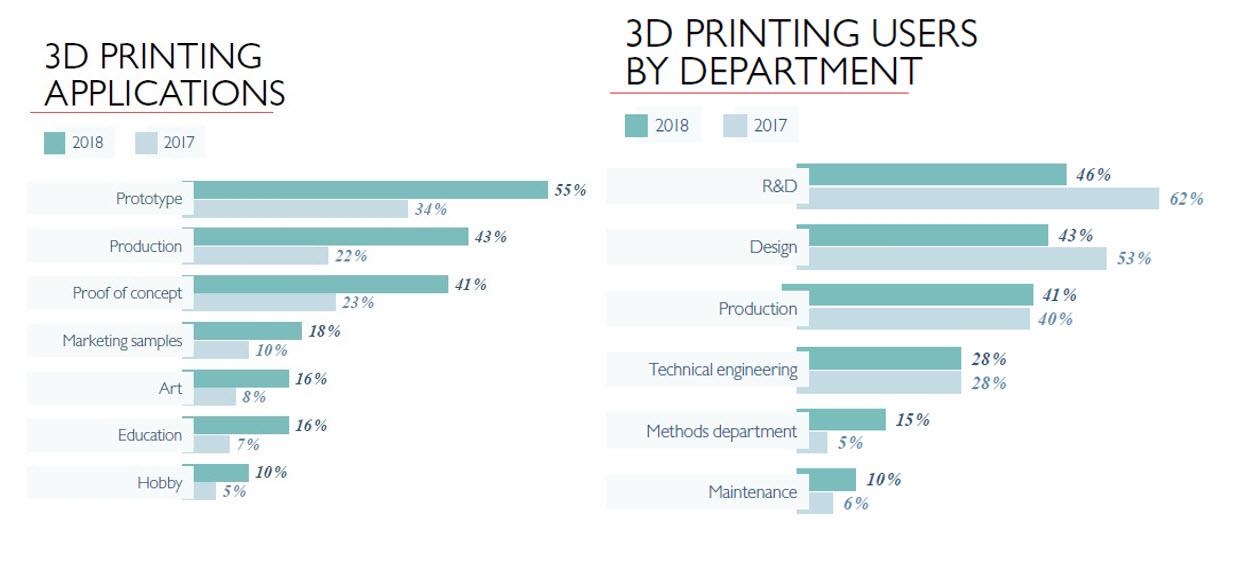

A research interviewed with 1,000 respondents distributed globally with 60% in Europe, 25% in America, 9% in Asia and Oceania, and 1% in Africa. They found that Prototyping (55%), production (43%) and Proof of Concept models (41%) are the three most popular 3D printing applications in 2018.

Source:Forbes, IKMResearch,2018

The acceptance and consumption of 3D printing in the company are arising. 38% of companies spent between $1K to $10K on 3D printing last year and those spending over $100K increased 3X, jumping from 4% in 2017 to 12% in 2018.

Source:Forbes, IKMResearch,2018

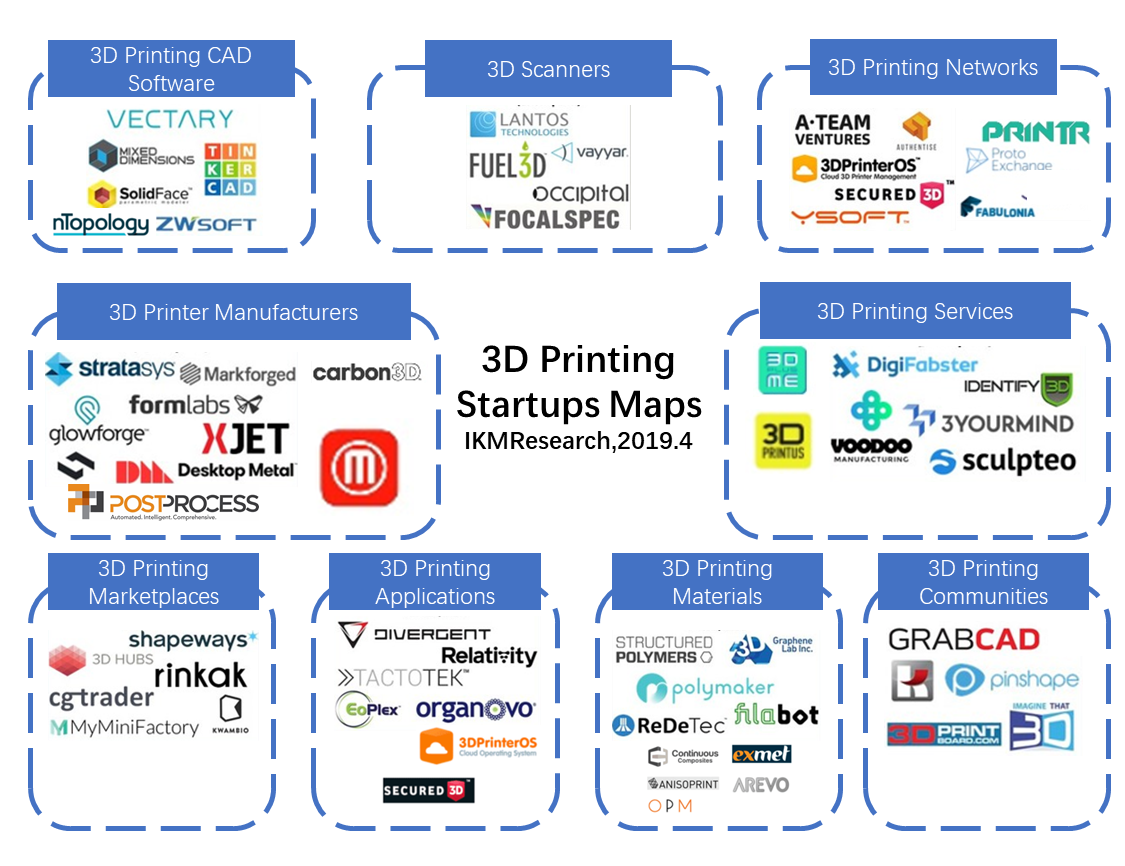

Over the past 30 years, 3D printing has developed a systematic ecosystem of software, machinery, and processes.

Source:IKMResearch,2019.4

Formlabs is latest 3D printing startup to join unicorn club. It was founded by 3 MIT graduates and is located in the suburbs of Boston. The company produced its first 3D printer, targeted for professionals, with a successful Kickstarter campaign that raised $3 million in 2012. Today, Formlabs has more than 500 employees, a revenue run rate above $100 million, and it claims to be the world’s largest seller of stereolithography 3D printers worldwide. It has about 20 investors, many of whom have participated in more than one round.

Carbon is the most well-funded and valuable 3D printing startup. Carbon counts some pretty high-profile names among its investors, including GE, Sequoia, Johnson & Johnson, Fidelity, BMW, Nikon and Google. It gained quite a bit of press last year when news broke that its 3D technology was being used to produce midsoles for Adidas footwear.

Desktop Metal is the first 3D printing startup unicorn. Its Production system claims to be 100 times faster than other 3D metal printers but at 20 times lower cost.

The 3D printing market is set to double in size every three years with the annual growth forecasted by analysts varying between 18.2% and 27.2%.